Graphite block

High temperature resistance: The melting point of graphite blocks is as high as 3800℃ and the boiling point is 4000℃, which can remain stable in high temperature environments. Conductivity: Graphite blocks have good conductivity. The carbon atoms inside are arranged in a hexagonal honeycomb shape. Each carbon atom has a free electron, which can move freely inside the graphite block. Thermal conductivity: The thermal conductivity of graphite blocks is also very good, and heat energy can be transmitted through vibrations between carbon atoms. Chemical stability: Graphite blocks show good chemical stability at room temperature and pressure and do not react with most chemicals.

Description

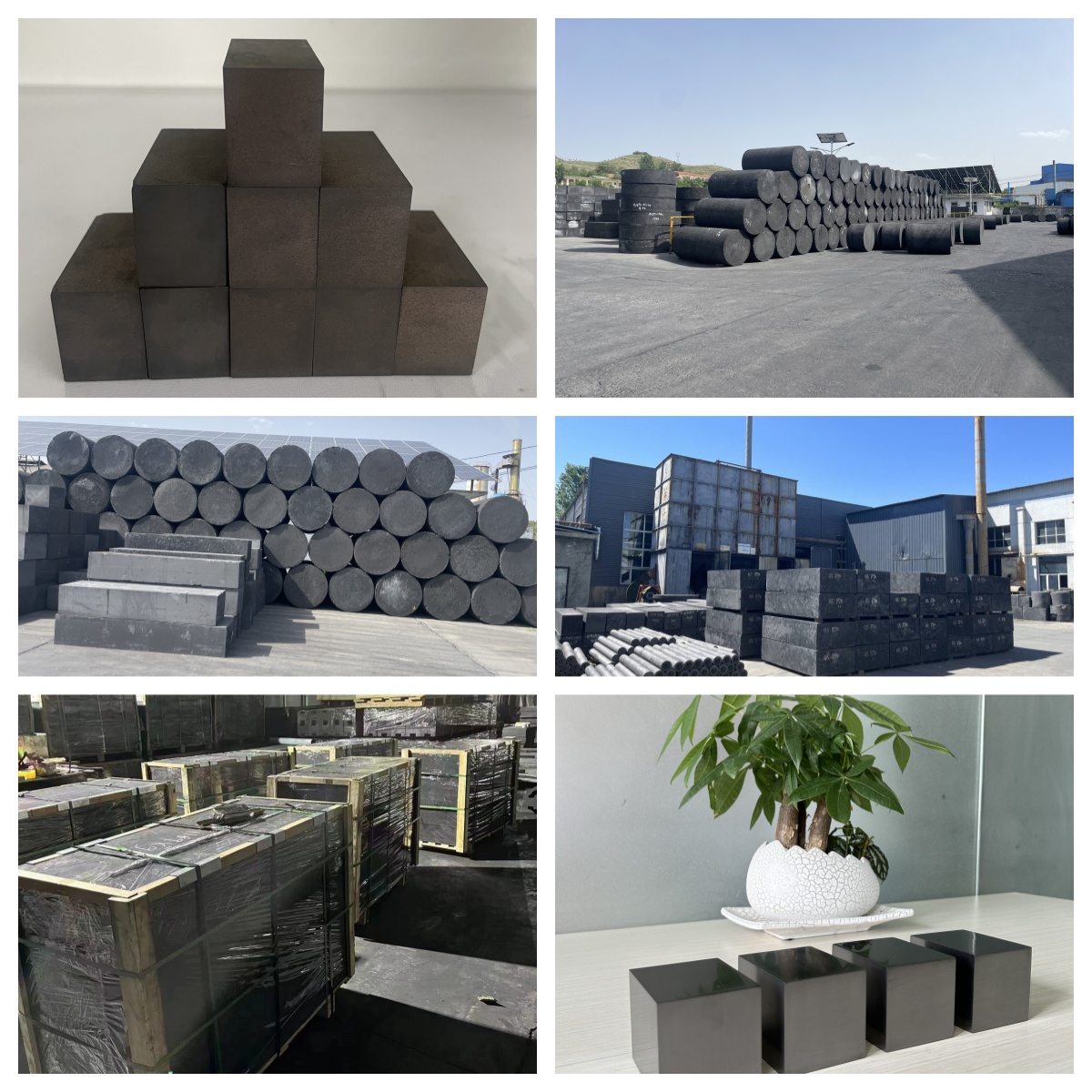

Graphite block is a material processed from pure graphite or graphite powder. It has many excellent physical and chemical properties, so it is widely used in many fields. The following is a detailed introduction to graphite blocks:

1. Characteristics

High temperature resistance: The melting point of graphite blocks is as high as 3800℃ and the boiling point is 4000℃, which can remain stable in high temperature environments.

Conductivity: Graphite blocks have good conductivity. The carbon atoms inside are arranged in a hexagonal honeycomb shape. Each carbon atom has a free electron, which can move freely inside the graphite block.

Thermal conductivity: The thermal conductivity of graphite blocks is also very good, and heat energy can be transmitted through vibrations between carbon atoms.

Chemical stability: Graphite blocks show good chemical stability at room temperature and pressure and do not react with most chemicals.

Corrosion resistance: Graphite blocks have good corrosion resistance to most chemicals and can remain stable in a variety of chemical environments.

Low density and high strength: Graphite blocks are a lightweight material, but the strength is very high, which makes it perform well in certain applications that require light weight and high strength.

2. Application

Aerospace: Graphite blocks have high temperature stability and high strength characteristics, so they are widely used in aerospace engines, thermal protection systems, aerodynamic thermal structures and other components.

Semiconductor manufacturing: Graphite blocks have high thermal conductivity and high chemical stability, so they are widely used in the semiconductor manufacturing field to manufacture key components such as graphite electrodes and graphite substrates.

Chemical processing: Graphite blocks are used in chemical reactors and catalyst carriers, and their high chemical stability and corrosion resistance make them an excellent material choice. In addition, graphite blocks can also be used in the manufacture of equipment such as storage tanks and pipelines.

Battery manufacturing: Graphite blocks are used as negative electrode materials for lithium-ion batteries. Their high conductivity and good cycle stability can improve the performance and life of the battery. At the same time, graphite blocks can also be used as negative electrode materials for batteries such as lead-acid batteries and fuel cells.

Coatings: Graphite blocks can be used to manufacture high-performance coatings, providing good conductivity and heat resistance, and are widely used in aerospace and automotive fields.

Heat exchangers: Graphite blocks are used to manufacture high-efficiency heat exchangers due to their good thermal conductivity. This material can maintain excellent thermal properties at high temperatures.

Lubricant: The low friction coefficient of graphite blocks makes it an excellent lubricant. Applying a graphite layer on mechanical moving parts can significantly reduce friction and improve mechanical efficiency.

3. Production process

The production process of graphite blocks usually includes steps such as graphite ore selection, graphite roasting, graphite crushing, graphite mixing, graphite pressing and graphite processing. During the production process, it is necessary to ensure the purity and quality of the raw materials, and strictly control factors such as temperature and pressure in the processing process to ensure the quality and performance of the product.

4. About us

Henan Yiguan Import and Export Co., Ltd. is one of the domestic manufacturers specializing in the production of graphite molds. The raw materials used by our company, such as isostatic graphite, molded graphite, and EDM graphite, have the characteristics of high strength, good thermal shock resistance, high temperature resistance, corrosion resistance, and strong oxidation resistance. The main products are: graphite molds, graphite crucibles, graphite plates, graphite rods, graphite tubes, graphite boxes, graphite blocks, graphite heaters, and various special-shaped graphite accessories, etc., which are widely used in metallurgical casting, solar photovoltaic, electronic semiconductors, new energy batteries, mechanical processing, industrial furnace high temperature treatment, diamond sintering, EDM, glass, chemical and nuclear industries.

Our company has long been committed to the development of the graphite processing industry, and is equipped with a series of advanced processing technology and equipment, and has established a special quality inspection department to ensure the quality of the company’s products. We can provide graphite processing services according to customer requirements, and process according to customer specifications, technical drawings and sketches. We use our processing technology and advanced processing equipment, as well as experienced processing technicians to produce perfect graphite products for customers.

In addition to mechanical processing, we also provide post-processing services such as graphitization and purification, and provide customers with perfect product services at preferential prices.

The company has always been adhering to the principle of “customer first, considerate service”, thinking about what customers think and what customers are anxious about, and making progress together with users in the field of graphite products to create brilliance.

In summary, as an important material, graphite blocks play an irreplaceable role in many fields such as aerospace, semiconductor manufacturing, chemical processing, battery manufacturing, coatings, heat exchangers and lubricants. With the continuous advancement of science and technology and the development of new materials, the application prospects of graphite blocks will be broader.

Send Inquiry

You Might Also Like

- * no